Where are you shopping for today?

Delivery State:

More Information - Klip-Lok® 700 ZINCALUME® Roofing Sheets

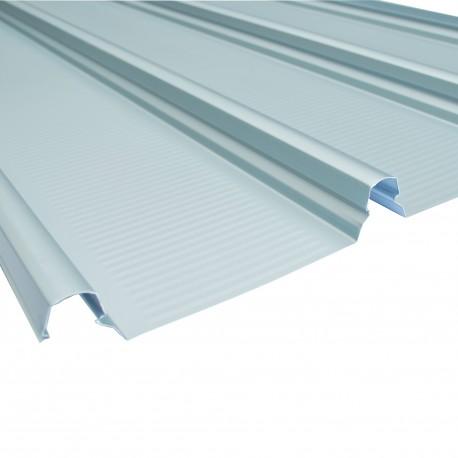

The ZINCALUME® Klip-Lok® 700 roofing profile is one of Australia’s most trusted concealed-fix systems, engineered for both architectural style and structural performance. Manufactured from genuine .48 BMT BlueScope® ZINCALUME® steel, it offers outstanding corrosion resistance, superior water-tightness and a clean, modern appearance with no visible screws.

Designed for Strength and Style

Klip-Lok® 700 features a wide 700 mm coverage that minimises laps and speeds up installation. Its high-rib design delivers exceptional spanning capability, making it ideal for commercial, industrial, and architectural roofing projects that demand both form and function. The concealed-fix clips allow the sheets to expand and contract naturally, reducing stress on fasteners and preventing roof leaks over time.

Applications and Suitability

Suitable for roof pitches as low as 1°, Klip-Lok® 700 is commonly specified for factories, warehouses, patios, and architect-designed homes. It’s also widely used for wall cladding and facades where crisp horizontal or vertical lines are desired. The ZINCALUME® coating ensures long-lasting protection in coastal, rural, and urban environments.

Manufactured to Your Requirements

Every sheet is custom-cut to your specified length for precision installation and minimal onsite waste. Length tolerance is +0 / –15 mm, and width tolerance ± 4 mm. When using long runs, allow for thermal movement to maintain roof integrity. All sheets are produced to AS 1397 and AS/NZS 2728 Australian Standards for steel quality and coating performance.

Why Choose ZINCALUME®

ZINCALUME® steel combines aluminium, zinc and silicon to deliver up to four times the corrosion protection of standard galvanised steel. It’s lighter to handle, energy-efficient, and highly reflective — helping keep buildings cooler in summer. For homeowners or builders seeking a long-term investment, ZINCALUME® Klip-Lok® 700 offers exceptional value and lifespan.

Installation & Accessories

Klip-Lok® 700 sheets use a concealed clip-fix system that simplifies installation and maintains watertightness. Ensure the roof structure is clean and aligned before laying sheets, and use the recommended Klip-Lok® fixing clips supplied by BlueScope® or an approved manufacturer. Complement your roof with custom flashings and matching gutter systems for a complete, weather-sealed finish.

Delivery & Turnaround

Orders are typically dispatched within 3 – 6 business days, depending on location and sheet length. We provide fast, reliable delivery throughout Victoria, New South Wales, Queensland, Tasmania and the ACT. Every order is packed with protective handling to ensure your roofing arrives in perfect condition, ready for installation.

Warranty & Compliance

All ZINCALUME® Klip-Lok® 700 sheets are backed by the official BlueScope® Steel warranty, giving you lasting peace of mind. The product complies with FM Global testing for wind uplift and watertightness and meets or exceeds Australian building code requirements. Always install according to the manufacturer’s specifications for warranty validity.

Why Order from Metal Roofing Online?

- ✔ 100 % Australian-owned business with direct supply from BlueScope® Steel

- ✔ Competitive online pricing and instant quoting

- ✔ Secure online checkout and responsive customer support

- ✔ Fast regional delivery across VIC, NSW, ACT, QLD

Frequently Asked Questions

Q: What roof pitch is required for Klip-Lok® 700?

A: It can be installed on roofs with a minimum pitch of 1°, provided drainage design complies with the manufacturer’s recommendations.

Q: How is ZINCALUME® different from COLORBOND®?

A: ZINCALUME® has a silver metallic finish and exceptional corrosion resistance, while COLORBOND® includes a pre-painted coating for colour choice and added surface protection.

Q: Are Klip-Lok® sheets available in COLORBOND® colours?

A: Yes. The same Klip-Lok® 700 profile is available in both COLORBOND® and ZINCALUME® finishes.

Q: How long does ZINCALUME® roofing last?

A: When installed correctly and maintained, ZINCALUME® roofing typically lasts 30 – 45 years depending on environmental exposure.